Electric Servo actuator-A perfect replacement of pneumatic cylinder for fairground ride in amusement park

Traditionally, fairground ride in amusement park are all use pneumatic system.

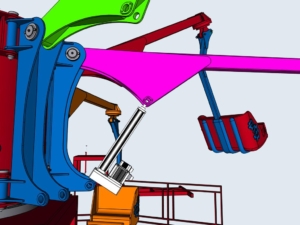

These types of rides push the gondolas up and down. They create a “Bounce” sensation using the cushioning air cylinders provide. Furthermore, these systems use a magnetic rod to tell the actuator where the arm is as well as the pressure requirements according to the weight of the passengers. They are operated via a pedal switch system in the ride control booth. However, these rides consump 30hp compressor. The problem with this is the power consumption. 30hp compressor uses 22KW. Besides, with this being a child’s ride, it needs to be as efficient as possible. For this reason, Our Electric Servo actuator are a perfect Replacement of pneumatic cylinder for fairground ride in amusement park.

The weight of the arm each actuator needs to lift will be a 500kg max with passengers.

The stroke is around 350mm. But this can be increased to suit off the shelf parts.

The speed of which it needs to extend is under 1s.

Each arm will extend and retract approximately 60 times per ride.

Our electric linear actuator offers quite motion. As a result, it gives visitors good experience. Also, electric actuators are maintenance-free and engery efficient. It would be a trendency for the replacement.

FAQ

Q1: How much liftime will we get from each actuator?

A1: Electric actuator manufactured by Shenzhen UNI Technology have 100,000km life.

Q2: Are parts easily replaceable?

A2: Yes. Our actuators are maintenance free. We will send extra timing pulley if parallel type preferred.

Q3: Does the system reliable?

A3: Electric servo system are more precise compared to pneumatic. Also, it is more energy efficient. It will be a trendency for the replacement in the next 5-10 years.